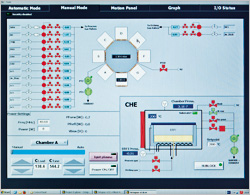

Automation Software

Flexibility

O

CTOPUS is an R&D / Pilot line dedicated tool, our main goal is to allow researchers to master all needed parameters in « manual mode » or « automatic mode ». Moreover, thanks to our clever software design, it is easy to update software, PLC I/O's, software security and hardware configuration according to customers needs.

Security

O

ne of our main concern while developing automation solutions is the security. All our process development tools contain a double stage security. First stage, Hardware Security PLC which is dedicated to security of humans and critical hardware. Second stage, Software security allowing or not users to activate valves, pumps, MFC, Power, Robot... Of course, for the sake of usability, both security stages can be disabled with administrative passwords to allow authorized personal to do maintenance.

User-friendly

O

ur automation software team developed our control software in close collaboration with end-users and researchers to fit their requirements in terms of usability, flexibility, security, easy-access for non-specialist operators (1. load your process recipe, 2. Press “Play” button, 3. wait for process to be completed). Our user interface is developed to be controlled with a touchscreen monitor which make even more comfortable the control of the different devices.

Features

- Friendly Graphic User’s Interface (GUI) inspired by production

equipment rather than traditional R&D equipment

- Password controlled user login with different levels of access

- Automatic process manager for:

- multi-chambers control

- multi-substrates control

- multi-recipes control

- Substrates tracking system

- GUI allowing Manual and automated control of:

- valve

- pump

- MFC

- RF Generator

- Substrate handling

- etc.

- Process & system data logging

Optical Diagnostics

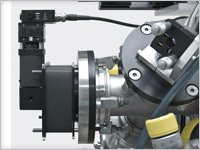

Laser-based powder detector

- Measurement of Si powder particles in the PECVD exhaust

- Time-resolved or steady-state measurements

- Particularly useful for microcrystalline deposition processes

- Designed for harsh environments

- Compact & flange-mountable

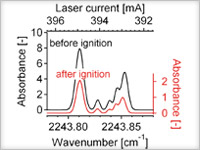

Infrared laser-based silane sensor

- Direct absorption measurement of SiH4 in the infrared

- Measurement in the exhaust or in the reactor of PECVD systems

- Steady-state or time-resolved measurements

- Determination of the SiH4 consumption efficiency,

the SiH4 concentration in the plasma, and more.

- Compact & flange-mountable

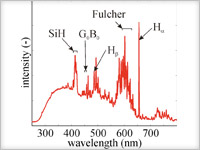

Plasma emission monitoring

- Control of the plasma stability

- Detection of powder formation

- Post-data treatment for better interpretation of optical emission

spectra

- Compact & flange-mountable

Ignition detector

- Optical detection of plasma ignition

- High sensitivity to detect plasmas with low emission

- Digital Output with adjustable threshold

- Analog output of plasma intensity

- Standard optic fiber connector for easy installation